Category

2018 New Technical High Performance Hammer Mill for Gold Ore

2018 new technical high performance hammer mill for gold ore Introduction of hammer mill for gold ore hammer mill for go

Basic Info

| Model NO. | HM4008-75, HM4012-90, HM4015-132 |

| Condition | New |

| Spare Parts Supply | for Whole Year |

| Test&Installation | Engineer Assigned |

| After-Sale Service | for Whole Using Year |

| Export Markets | Global |

| Transport Package | Container, Nude Packs, in Bulk |

| Specification | ISO9001: 2000 |

| Trademark | Zenith |

| Origin | Shanghai Zenith, China |

| HS Code | 8474209000 |

| Production Capacity | 80sets/Month |

Product Description

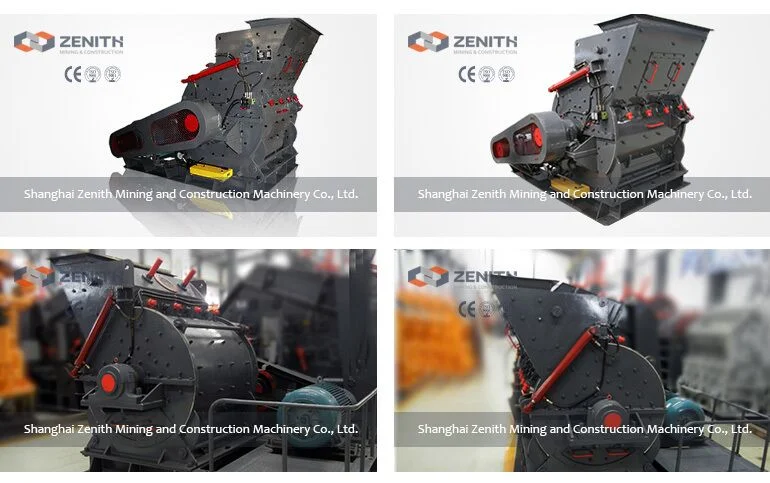

2018 new technical high performance hammer mill for gold oreIntroduction of hammer mill for gold ore

hammer mill for gold ore is composed of body, rotor, hammer head, counterattack liner, sieve plate, etc. Hammer crusher plant is mainly used for crushing medium-hard or brittle materials with hardness not more than 150Mpa and moisture within 15%, such as coal, salt, chalk, plaster, brick, limestone, etc. hammer mill for gold ore also can be used for crushing fiber, elastic and resilient wood and paper, or crushing the asbestos waste. Thehammer mill for gold orecan be not only applied in the crushing production line and sand production line, but also used for replacing cone crusher in the ore beneficiation line.

Working Principles of hammer mill for gold ore

1. The main working part of hammer metal crusher is rotors with hammer.

2. The rotors consist of main shaft, disk, pin shaft and hammers.

3. The motor drives the rotors to rotate quickly in the crushing cavity.

4. Raw materials enter the crusher through the feed opening and are stricken, impacted, cut and grinded by the high-speed hammer to small size.

hammer mill for gold ore Working Principle :

hammer mill for gold ore is made up of the frame, rotor, impact iron bar, grid bar and other components. When the hammer mill for gold ore works, spindles and rotor rotating which are drived by the motor and V-belt, and then centrifugal force producing by the hammer rotates materials spread out. It will be crushed by the high speed hammer when the big material put into crushing chamber. After those crushing stages, standard materials will be screened out by the down bar, the materials which are not standard will be left on the crushing chamber and re-crushed again. In order to avoid clogging, customers should pay attention to the humidity of the materials, the humidity of crushed material should below 10%-15%.

hammer mill for gold ore application

hammer mill for gold ore is mainly used for crushing medium hardness materials in the industry of cement, chemicals, electric power, metallurgy etc. It is suitable for the mid-crushing and fine crushing of materials like Stone/Granite/Basalt/Pebble/Gravel/Gypsum/Sillica Sand/Limestone etc. By using the hammer mill for gold ore, the matreial with particle size of 600-1800mm can be crushed directly intogranularity of 25mm or less than 25mm.

hammer mill for gold ore technical data

| Name & Model | HM4008-75 | HM4012-90 | HM4015-132 | |

| Rotor diameter(mm) | 750 | 900 | 1150 | |

| Rotor length(mm) | 800 | 1200 | 1500 | |

| Rotor speed(rm) | 800-1000 | 800-1000 | 550-800 | |

| Feeding size(mm) | 320×930 | 400×1200 | 500×1500 | |

| Max feed size(mm) | <30 | <40 | <50 | |

| Discharge size(mm) | 0-3 | 0-3 | 0-8 | |

| Theory processing capacity(th) | 8-15 | 15-40 | 40-70 | |

| Motor | Model(Standard) | Y280S-4 | Y280M-4 | Y315L2-6 |

| Power(kw) | 75 | 90 | 132 | |

| Rotate speed(rm) | ||||

| Hammer number(pcs) | 18 | 32 | 32 | |

| Dimension(L×W×Hmm) | 2130×1665×1610 | 2840×2100×2020 | 3720×2650×2540 | |