Hot Selling Flat Die Feed Machinery Animal/Feed Pellet Making Machine

Basic Info

| Model NO. | 125-400 |

| Expanding Method | Dry Expansion |

| Condition | New |

| Applicable Materials Shape | Short strip |

| Product Name | Feed Pellet Making Machine |

| Factory | Henan Hongke Heavy Machinery |

| Factory Visit | Welcome Warmly |

| Quality | High Level |

| Capacity | 80-1200 Kg/H |

| Suitable for | Corn Powder,Meat Powder, |

| Transport Package | Container |

| Specification | 125-400 |

| Trademark | Hongke |

| Origin | China |

| HS Code | 8436100000 |

| Production Capacity | 500 Units Per Month |

Product Description

Hot Selling Flat Die Feed Machinery Animal/Feed Pellet Making Machine

Brief Introduction of Feed Pellet Making Machine

| Name | Feed Pellet Making Machine |

| Suitable for | Chicken, fish, cow, sheep, duck,rabbit, etc. |

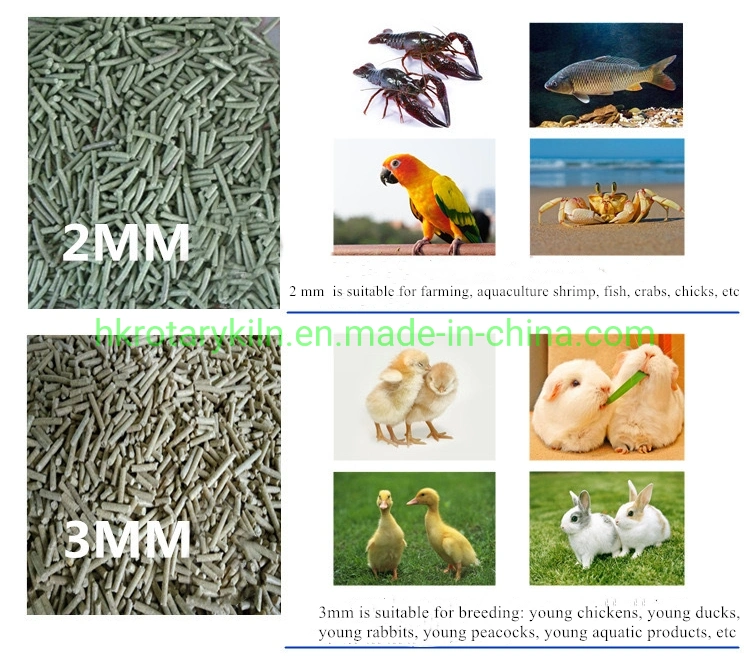

1). This feed pellet making machine is used to produce pellet feed for pig, cattle, sheep, rabbit, chicken, duck, fish,etc;

2). The raw material could be corn,soybeans,fish meal,wheat bran,grass,alfalfa,straw etc materials.

3). The moisture content of material could be: 12-16%.

4). The size of materials could be: 4-6mm.

Application of Feed Pellet Making Machine

Feed Pellet Making Machine works on a vertical design, using gravity as the main force for feeding the material through the machine.

Feed Pellet Making Machine has a horizontal die, with a series of rollers sitting on the die. When material goes in from the top feed inlet, it is compressed between the rollers and die.

Functions and Usage of Feed Pellet Making Machine

Feed pellet making machine is based on the raw material of corn meal, flour, Wheat middling, Wheat bran , rice bran, soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc.

Then the material can be expanded to pellet feed which is different shaped, unique taste and rich nutrition, suitable for dog, cat, fish, bird, rabbit fox etc.

Structure of Feed Pellet Making Machine

Techinical parameters of Feed Pellet Making Machine

More Pictures of Feed Pellet Making Machine

Company Introduction

Henan Hongke Heavy Machinery is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers, agricultural machines and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

FAQ

1. What is the minium order quantity?One set.2.How long is the warranty period?One year. Wearing parts are excluded.3. What is the after-service of your company?We can provide the customers foudation drawing, installation service, work training as well as other service according to thecustomer's requirements.4.How long is the delivery time?About 15 days after we receive the payment.5. What are the payment terms?T/T, L/C are the best, it can be adjustable according to different situations.--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.2. Please Inform us the follow figures:1). feeding material2). Feeding material MAX. Size (mm)3). Final mesh size (mm)4). Capacity (t/h)

Upon we got your message we shall give you our favorable offer in short time.