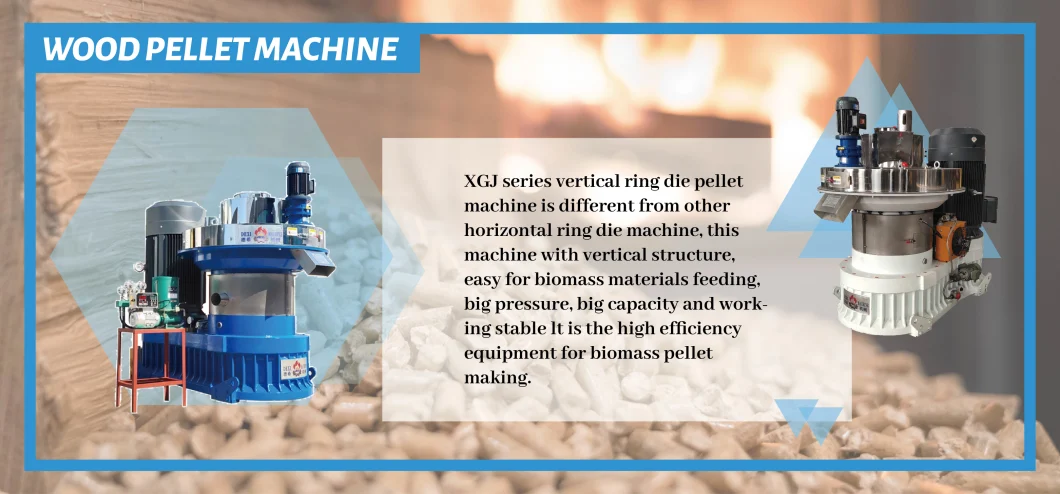

132kw 2 Ton/Hour Vertical Ring Die Big Capacity Industry Using Biomass Pelletizing Wood Pellet Press Making Pelletizer Mill Machine

Basic Info

| Model NO. | XGJ560P |

| Type | Vertical Ring Die Pellet Machine |

| Voltage | Customized |

| Automatic Grade | Automatic |

| Controlling Mode | Artificial |

| Energy Saving | Energy Saving |

| Certification | CE |

| Warranty | 3 Years |

| Customized | Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | Whole Working Lifetime |

| Materials | Wood Rice Husk Straw |

| Power | 132kw |

| Capacity | 1.5-2t/H |

| Spare Parts | Die, Rooler and Bearing |

| Die Materias | Stainless Steel |

| Cover of Pelletizing Chamber | Stainless Steel |

| Roller | with Wear-Resistant Material Tungsten Carbide |

| Transport Package | Bulk in Container |

| Specification | 2600x1250x1600mm |

| Trademark | DEXI |

| Origin | China |

| HS Code | 84793000 |

| Production Capacity | 30 Sets/Month |

Packaging & Delivery

Package size per unit product 260.00cm * 125.00cm * 160.00cm Gross weight per unit product 4600.000kgProduct Description

132kw 2 Ton/Hour Vertical Ring Die Big Capacity Industry Using Biomass Pelletizing Wood Pellet Press Making Pelletizer Mill MachineProduct Description

In the video is our ring die pellet machine, the model of this machine is 132kw-XGJ-560P,it's output capacity is 1500-2000kgs/hour, the pellet diameter can be 6 mm, or 8 mm or 10 mm by change ring die.XGJ560P wood pellet maker machine is mainly using for press different kind of biomass materials into cylinder shape pellets, the output pellets is good green fuel energy for fireplace or industry biomass burner. XGJ series CE certificate wood pellet machine is our main product which has adopted the essence of pellet mill in oversea market.

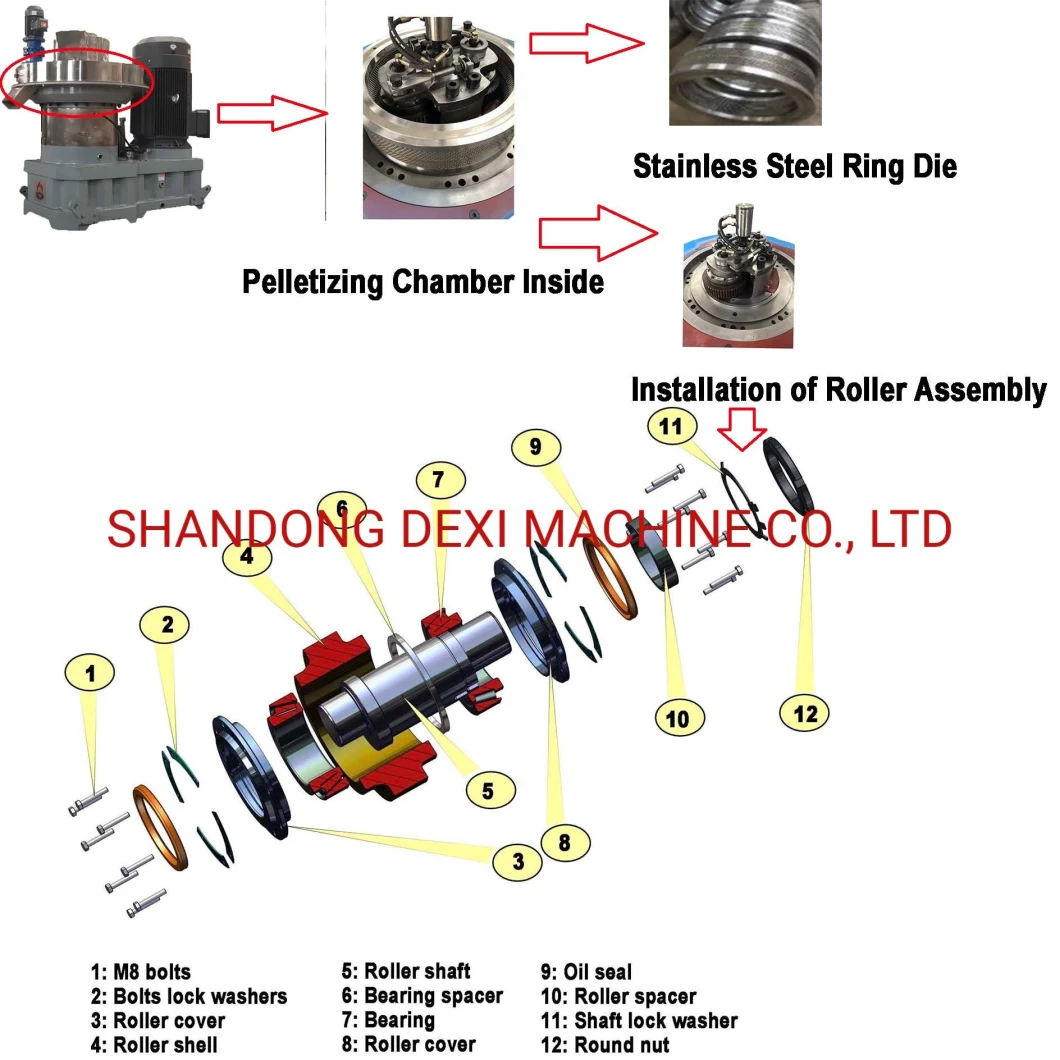

Detailed Photos

1. Famous Motor: The motor is a famous brand motor with a three-year warranty.2.Big&Stable Gearbox: In the gearbox, the transmission is stable, low noise , the service life is long, and it can withstand high power and heavy load.3. Gear Oil Lubrication Pump&Motor: The gearbox has its own lubrication and cooling system, which can cool down the lubricating oil without stopping the machine to ensure long-term operation.4. Feeder Hopper: This design can avoid the raw material be stuck in pelletizing chamber.5. Pelletizing Chamber Inside: The pelletizing chamber inside including the double layer ring die which made of astainless steel and the roller assembly,these two parts have the following characters: Particular design, reasonable structure, low energy, high efficiency, long life and so on.6.Hydraulic Oil Cooler: Cooling the oil which inside the big gearbox.

Product Parameters

| Model | Power (kw) | wood pellets makingCapacity (kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| XGJ460 | 55+1.5+0.55+1.5 | 500-800 | 4200 | 2600x1100x1850 |

| XGJ460P | 55+1.5+0.55+1.5 | 500-800 | 3200 | 2300x1100x1500 |

| XGJ560 | 90+1.5+0.75+0.55+2.2 | 1000-1500 | 6100 | 2600x1300x2300 |

| XGJ560P | 132+1.5+0.75+0.55+2.2 | 1500-2000 | 4600 | 2600x1250x1600 |

| XGJ700P | 160+1.5+0.75+0.55+2.2 | 2000-2500 | 14500 | 3300x1400x3100 |

| XGJ850 | 220+3+0.75+0.55+3 | 2000-3000 | 9600 | 2600x1600x1950 |

| XGJ850P | 220+3+0.75+0.55+3 | 2500-3500 | 13500 | 2650×1850×2100 |

| XGJ850P | 250+3+0.75+0.55+3 | 3000-4500 | 15000 | 2750×1850×2100 |

Machine's Advantages:

1.XGJ560P wood pellet maker machine is update version of XGJ560, the machine with big strong industry gearbox, make the motor and machine shaft directly connected with the gearbox, improve the transmission efficiency, make the machine stronger and more stable.

2.The ring die is made of double-layer stainless steel. 3.the motor is a famous brand motor with a three-year warranty. 4.This wood pellet maker with totally automatically lubrication system, the gearbox with lubrication pump let the gear oil cycle lubrication of each bearing and gear. 5. And there also another grease pump regularly inject grease to the roller bearing. So, this machine can long time no stop continually working.

Pellet making process:

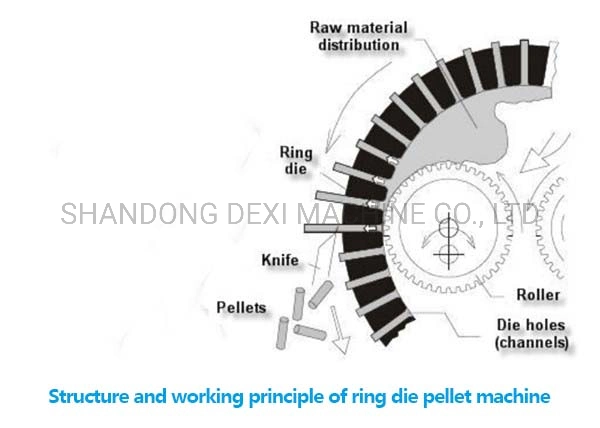

Wood pellet making machine is mainly applicable for difficult molding materials with low adhesion rate, for example, hard wood sawdust, rice husk, sunflower husk, peanut shell and fruit shell; branch, stem, bark and other wood waste; a variety of crop stalks; rubber, cement, ash and other chemical materials.When working, material from feeding mouth vertically to the roller frame board surface, through the rotation of the roller frame board, continuous uniform within the mold cavity surface. (the surface for roller connected ring die), under the roller rolling powder material through the die hole (Uniformly distributed in the inner surface of die).This process is the role of material under high pressure, high temperature, produce a physical change or proper chemical changes(depends on different kind of raw materials ), make the powder material form elongated cylindrical solid body, the cylindrical solid elongation continuously will be cutting by uniformly distributed around the mold cutting knifes, become to "pellets" the pellet pusher will collecting the pellets to the outlet place. (Product structure chart) Pellets under the action of gravity automatic fall, this pellet making process is complete.

The Auxiliary equipment :

1.The Control Cabinet .2.The Auto-lubrication Grease Pump.3.Dust Remove System.Application:

Packaging & Shipping

Certifications

Factory Tour